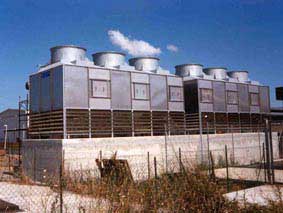

Cooling towers revamping: Boldrocchi TE industrial revamping service

We are specialized in Cooling Towers Design and construction: if you are looking for Cooling Towers revamping, Boldrocchi TE Revamping Service will help you to choose betweeen our different Cooling Towers solutions!

Ecology

Ecology is a fashionable word: it is in utterly every idea, resolution, promise and plan; it is nearly impossible not to come across it whatever the discussion is at hand.

In time, we fear, this word may become abused and may lose its original idealistic connotation which marked its birth and dissemination, or maybe this has already happened for some time at least in some areas of human knowledge.

As a result, this word may be used just as a trendy expression with no real intention of conveying any practical sense to it; maybe this is just because we think that what could be done has been done and any further progress is far-fetched.

Conversely, at Boldrocchi T.E. we believe in the message conveyed by the word "ecology" and, in our small way, we do our best to make it a reality in every project we do.

A far as we are concerned, we have identified three possible elements to work on in our equipment:

1) Selection of durable components;

2) Savings on water consumption;

3) Reduction or simplification of product disposal.

However, we have not found a way yet accepted by the market, to reduce the electric power needed for operation, although this is minimal.

Unless really revolutionary innovations are brought about, a reduction in the electric power used is a hazardous choice rather than a goal attained; this is due to the kind of fills known nowadays which set the air quantity necessary to ensure the required evaporative process, and to the efficiency of fans allowed, to the relatively economical version permitted by the market.

Specifically, points 1 and 3 are somehow connected for disposal of components is reduced accordingly, if durable components are used, which do not call for any replacements during the cooling tower life cycle -or just occasional ones - or the tower itself is so robust to guarantee a longer-than-average life cycle.

We have already mentioned how the metal casing is treated in order to prevent it from being damaged by corrosion; in this way long life is ensured and the need for replacements is kept at bay.

However, the main component - a blessing and a curse for all managers or users of cooling towers - is without a doubt the fill (wet deck, evaporative surface, etc.).

As time goes by, the crucial component - the very heart of any cooling tower - becomes dirty, deteriorated, cannot guarantee optimal efficiency therefore needs replacing. It may or may not be subjected to the efficiency of the make-up water system, as the agent under question is actually to be found in the air element.

Most of these components are made of plastic. The most common - which is to say the most economical and best performing when clean - are made of PVC; however, they are all processed from hydrocarbons.

The more fills replaced, the higher the consumption of hydrocarbons; the fewer fills replaced, the less material to be disposed of, which is often a complex operation.

Moreover, the less material to replace, the fewer problems and costs to face.

Although commonly shared by field professionals, we believe an explanation is worthwhile.

The evaporative process reaches its climax inside the fill, where the two process fluids come into contact - the water to be cooled and the cooling air.

Simply said, the closer and longer the contact, the higher the efficiency of the cooling tower.

Thanks to small and numerous passages a larger total surface can be obtained and as a result a closer contact of the fluids.

The small passages are obtained using quite thin PVC or propylene corrugated sheets which are heat-sealed and then coupled.

Existing water deposits can obstruct these small passages; water deposits may also build up due to air. Water acts as a filter and detects all possible impurities in the air.

Mechanically speaking, the sheets composing this fill - called "film-type fill" - are very weak and easily rot when exposed to the mechanical action of irregular water jets especially if they derive from partially obstructed spray nozzles. As a result, the fill made up of the sheets may be more likely to clog.

As a consequence, scheduled replacement of this component may be seen as the only solution despite being expensive and troublesome.

As required by the market, our Company offers the type of fill described above; however, for environmentally friendly and economical reasons we also offer a different sort of fill known as "Splash", or ?Splash fill surface?.

Made of injection moulded propylene, dirt-resistant and mechanically robust, this fill can be described as everlasting, without ever needing replacement in the entire life span of the cooling tower which hosts it. Once again, the equation non-replaced component = no need for disposal holds true.

Water consumption is physiologic and necessary in the evaporative process: if water is not evaporated, no heat is removed from it.

However, besides evaporated water, an additional loss must be taken into account; this is called ?entrainment? or ?drift? and is often tiny, yet present.

The air flow carries away water droplets which would be dispersed if suited components named drift eliminators which intercept droplets and prevent them from being deposited outside the cooling tower itself where not in place.

Unfortunately, these components are not perfect, therefore a certain quantity - which may very due to several factors such as water flow/surface unit, air speed, droplet size, etc. - escapes the drift eliminators and is dispersed into the environment.

Again, we have always informed our clients that a modest investment made at the beginning or also once the system has been operating in some cases, can guarantee drift eliminators whose efficiency has been recognised by a prestigious Institute esteemed worldwide.

We would like to thank all clients who have chosen and will choose in the future the alternative solution proposed: we strongly believe in it as our small - or relatively small ? contribution to the saving on a crucial resource such as water.