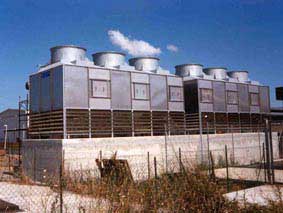

Evaporative Cooling Towers

What are evaporative cooling towers

Evaporative cooling towers are heat dissipation systems that exploit the

principle of evaporation to cool a mass of water through an exchange of air with the

environment.

Forced evaporation removes heat from the water, causing it to cool.

This process has been known since antiquity, when it was applied through the use of

terracotta amphorae, which kept water cool by allowing very small amounts of water to ooze

out due to the porosity of the material.

What are evaporation cooling towers used for

To date, evaporative cooling towers are mainly used in industrial contexts, to disperse the

heat produced by machinery, and are essential in all processes where a thermal cycle is

present, in other words where there is a need to cool the water and then put it back into the

circuit.

Evaporative cooling towers, with a few simple measures, manage to cool

the water to below ambient temperature, because they exploit the principle of latent

exchange of evaporation.

Latent exchange of evaporation, unlike other systems that remain bound to the

room temperature as the attainable cooling limit.

How evaporative tower cooling systems are made

Evaporative cooling towers can be classified into natural draught towers and mechanical

draught towers.

Natural draught towers exploit the density difference between air and water vapor to

circulate air and therefore do not require fans.

Mechanical draught towers, on the other hand, are the most commonly used type of

evaporative cooling tower, and normally consist of: a containment structure perforated at the

base to allow air circulation through a fan, a system that distributes the water inside, and a

tank where it is collected once it has cooled and then recirculated.

How the evaporative cooling towers works

There are open-circuit and closed-circuit evaporative cooling towers.

To make the most of the latent heat exchange principle, open-circuit evaporative cooling

towers have a high contact surface area between air and water.

In this type of circuit, the tower receives a large quantity of water at high temperature, which

is distributed in the containment structure.

Through the heat exchanger (where heat exchange takes place between

water and air against the current), a small part of the water evaporates while the remainder

cools down.

The evaporative cooling towers can then be fed back into the industrial process. In towers

closed-circuit cooling towers, on the other hand, the process water does not come into direct

contact with the air, but remains inside a heat exchanger, and is therefore always free of

polluting components.

How the maintenance of these systems is carried out

Obviously, these processes dissipate water, because a small amount of it must necessarily

evaporate during the cooling cycle.

The salts contained in the water, however, remain dissolved in the remaining water,

increasing its concentration.

For this reason, it is essential to periodically check their levels.

In addition to this, anti-limescale treatments and partial purging should be carried out.

Industrial and civil applications of evaporative cooling towers

While natural draught towers are used in geothermal energy and in the construction of

nuclear power plants, mechanical draught towers are widespread in all industrial plants

where a constant cooling system is required due to the presence of delicate equipment.

However, they are also used in the civil sector, for example to keep water cold during the

summer season.

Due to their easiness of use and minimal maintenance requirements, evaporative cooling

towers

are the best solution for cooling industrial plants.

With the exception of the fan, they have no special mechanical components moving

constant motion, and consequently also allow considerable savings in electrical energy.