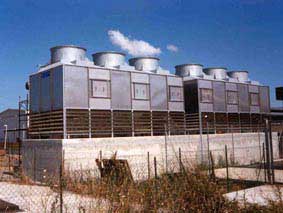

Cooling tower fills types & function

Discover more about filling system & best materials for cooling towers

The cooling towers are designed to cool the water as quickly and efficiently as possible. To do this, the water must flow over as much surface as possible - in order to provide the maximum possible contact between the air and the water. "" Fill "" is a medium used in cooling towers to increase the surface available for water.

There are two basic types of filling: block filling and sheet filling.

Splash fill cooling tower vs film fill cooling tower

The splash fill is designed to stop the water and cause, as the name suggests, splashes. The film filling, on the other hand, is made up of sheets of material that the water passes through. The fill pieces are assembled together to create larger blocks which, in turn, are used to create various thicknesses and heights to fit the particular cooling tower for which they will be used.

Fill is available in two main types: splash and film. Both types can be used in both crossflow and counterflow towers. But each type of filling has distinct advantages that make it more advantageous for specific conditions. The filling of the sketches works by causing the flowing water to slide through a series of parallel spray bars, which in turn cause water to splash (hence the name). Since the spray coverage provides the least opposition to the airflow in the horizontal direction, it is mainly used in cross-flow cooling towers. The depth of the filling pack (air path) is variable to provide the appropriate heat transfer area within a single fill level. If another fill layer is needed for the situations in which it is required, it will be limited to only one

A major advantage of spray filling is that it is very forgiving of insufficient initial water distribution, since spray activity redistributes water at each level of spray bars. For this reason, a spray-filled cooling tower effectively manages water containing debris (which has a tendency to interrupt the normal flow of water flow). Maintenance is also simpler, as its open nature provides easy visual inspection of the water flow diagram and filling conditions.

Sheet filling

Filled patterns, usually ridges or wrinkles, are called channels or flutes. The sheets are, in general, designed so that they force the water to take the longest possible route. The smaller sheets are cheaper because they allow a greater capacity per cubic foot. Larger sheets, however, are suitable for applications with dirty water (such as steel mills) because larger sheets clog less often than smaller flutes in these types of applications. The larger sheets sacrifice efficiency, but allow the processing of dirtier water.

Block filling

In extremely dirty applications the type of bar filling is used. The block-type filling allows much larger debris to pass through the cooling tower, as the filling takes the form of blocks sprayed along the entire tower. Although this is less effective filling, block-type filling allows you to process dirty water and clean it more easily.

If you want to know more about the best cooling tower fills types, feel free to contact us!

Find out the applications of cooling tower in food industry, how they work in steel plant